If you have been shopping for flooring recently or even if you are in the flooring industry you have probably noticed the massive influx of vinyl flooring options that have flooded the marketplace in recent years. While vinyl flooring is not a new category, many of its latest incarnations are. You might be familiar with acronyms such as VCT (vinyl composite tile) or LVT (luxury vinyl tile), but it seems like every manufacturer likes to come up with new terms and acronyms with every product release, and there has been no consensus historically of what those acronyms really mean. A few examples of this include the acronyms WPC and SPC. When we first started seeing these new flooring types emerge into the marketplace in 2012, many manufacturers referred to WPC as “wood plastic composite” because of a small amount of wood fiber mixed into the expanded foam core. Likewise, SPC was largely referred to “stone plastic composite” or “solid plastic composite” because of the limestone content within the solid core. Both were also referred to as “rigid core”.

We have tapped the knowledge of one of the vinyl flooring industry’s most seasoned professionals to help break it down for us. Mark Howe from US Floors/ Fusion (http://www.fusionvisionfloors.com/) is an industry veteran with decades of experience and a wealth of knowledge. We recently invited him to meet with several local interior designers to present this knowledge and the information that came out of that meeting was important enough that we decided to present it here for everyone’s reference.

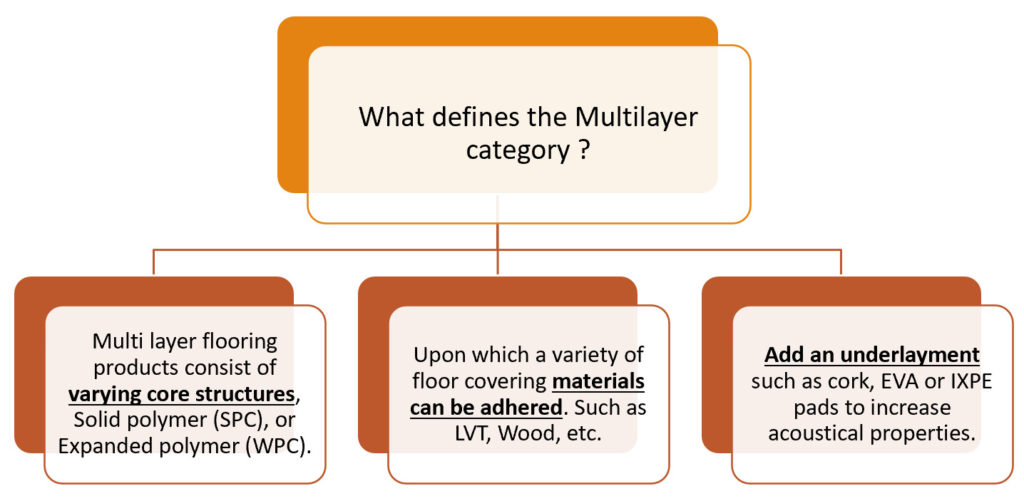

Just like the wood flooring industry has the NWFA (National Wood Flooring Association) as its governing body, the vinyl flooring industry created and adopted the MFA (Multi-Layer Flooring Association) as their governing body in 2016. According to http://www.multilayerflooringassociation.com/

“The mission of the Multilayer Flooring Association is to establish standards to insure the performance and safety of polymer composite core products for indoor residential and commercial environments, as well as monitor compliance of its members’ products through third party certification of these standards. In addition, the association will actively promote sustainability throughout both the life cycle of the product and the supply chain.”

Rigid core or polymer composite core flooring products = Multilayer Flooring

In December 2017 the MFA formalized the way we would refer to the flooring types within the multilayer category:

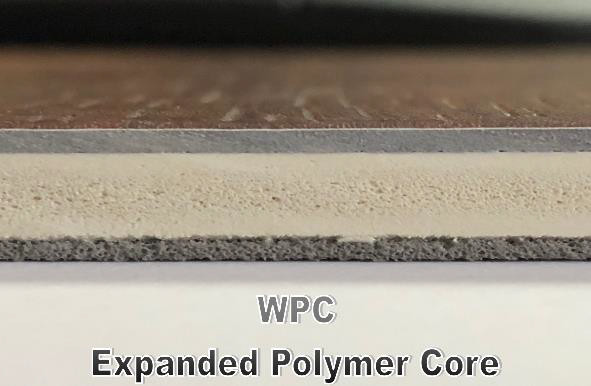

- WPC products represent the class of rigid vinyl flooring products with an expanded or foamed polymer core.

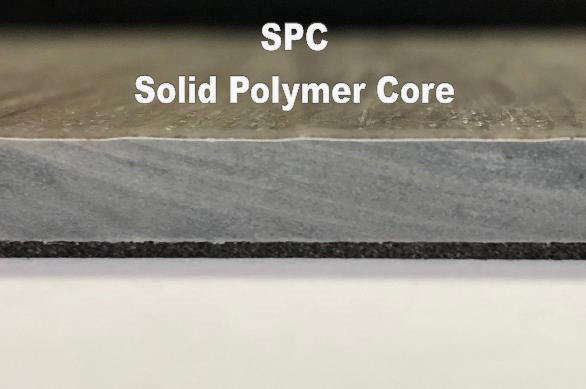

- SPC products refer to the class of rigid vinyl flooring products with a solid polymer core.

|  |

The pictures above show a side view of both flooring types.

Assembly is Key

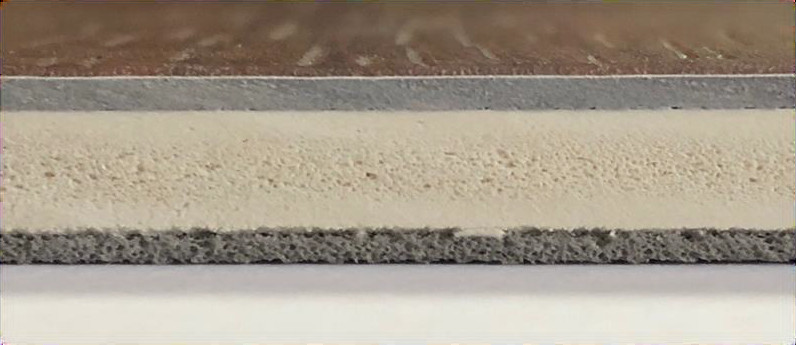

The key difference with WPC from SPC assembly is the LVT top and EXPANDED POLYMER core. A veneer of luxury vinyl is layered on top of the Expanded polymer core board and in addition a core underlayment is attached at the base for sound abatement and enhanced comfort underfoot.

WPC Assembly:

- Wood Plastic Composite is made from a blend PVC, limestone, foaming agents, inert ingredients.

- Laid down in powder form and pressed and heated to expand the polymer.

- The core material is waterproof, rigid and dimensionally stable.

- Approximately 50/50 PVC & Limestone.*

| Typical WPC Assembly 1. Wear Layer 2. Print Film 3. LVT * 4. Expanded Polymer Core* 5. Attached Underlayment |

SPC Assembly:

- Solid Polymer Core (SPC) is characterized by the solid nature of the core, regardless of material ingredients.

- Most SPC labeled products have a similar assembly which includes: Wear Layer, Print Film, Core, Underlayment.

- Not all SPC’s are built the same.

- If it does not have an expanded polymer core, it is an “SPC”.

| Typical SPC Assembly 1. Wear Layer 2. Print Film 3. Solid Polymer Core 4. Attached Underlayment |

Which is better WPC or SPC?

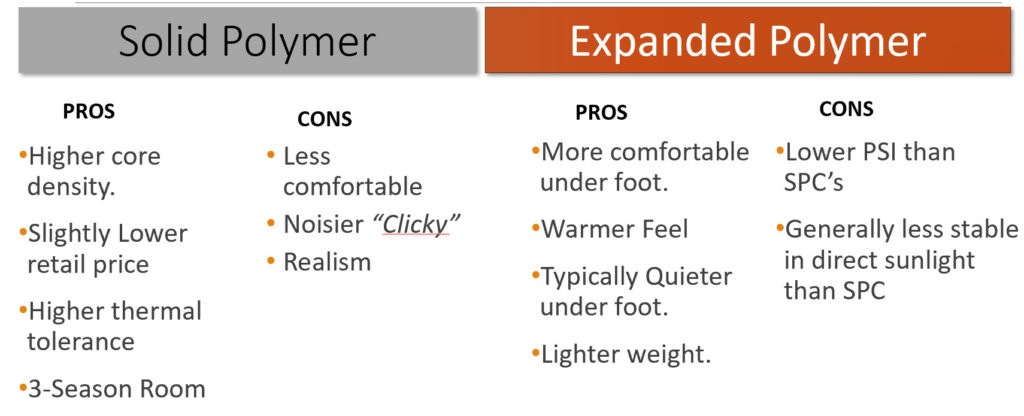

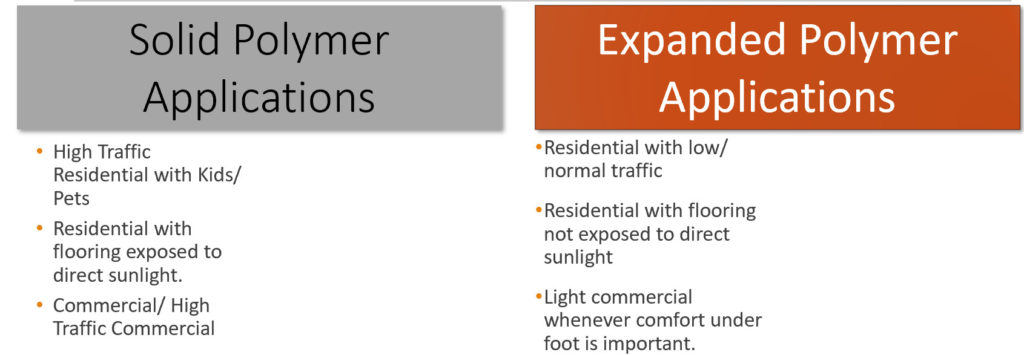

The answer to this question is simple as it is really the incorrect question to ask. The better question is which is better for the planned application as there are pro’s and con’s for both. SPC is the newer technology, but it is not necessarily better in a broad sense. The core determines which product is best suited for the application.

- SPC core is Generally 80% Limestone 20% PVC polymer and is not “foamed” therefore has a higher core density, creating a more solid underfoot feel.

- WPC is Generally 50% Limestone 50% PVC polymer w/expanded polymer core creates a more comfortable under foot feel.

Based on the core differences of WPC and SPC the application differences would include:

Attached Pad or Underlayment

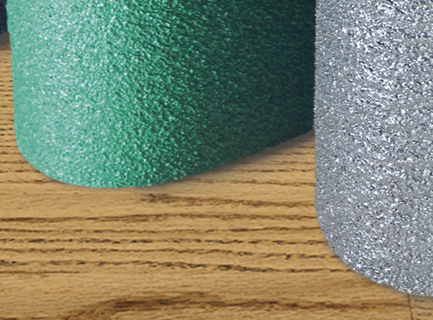

The next thing to consider when purchasing a WPC or SPC floor is the attached pad or underlayment which are added by the manufacturer to improve sound abatement and under foot comfort. There are three main categories of underlayment.

- Cork – All Natural, Sustainable, naturally contains SUBERIN (soo-BER-in) a waxy substance that resists mold and mildew, maintains gauge and acoustical integrity for the life of the floor.

- EVA – Ethylene Vinyl Acetate is an elastomeric polymer that produces materials which are “rubber-like” in softness and flexibility. EVA can be found in many consumer products such as Flip Flops, Pool Noodles, Croc’s and Underlayment for floating floors. EVA tends to lose its loft and acoustical properties over the life of the product.

- IXPE – Irradiated Cross-Linked Polyethylene, is a closed-cell foam that is 100% waterproof, and impervious to mildew, mold, rot, and bacteria. Offers superior acoustical ratings. Can be glued.

In a good, better, best scenario they are listed in order here with many of the premium products offering the IXPE pad in lieu of the EVA or Cork options.

It is estimated the multilayer flooring category will continue to gain market share for many years to come. Undoubtably we will continue to see innovations in this category as well. The establishment of the MFA has on-going efforts to standardize nomenclature, performance, and safety standards of these high demand flooring products. No matter if you are a homeowner, specifier, or flooring salesperson we hope that this brief explanation helps clear up some of the widespread confusion that exists. For more information you can visit the website of the MFA at http://www.multilayerflooringassociation.com/

You can visit www.denverhardwood.com for a large selection of commercial and residential multilayer flooring options.

Mark Howe is a 34-year veteran of the flooring business with much of that time working with the Vinyl category, specifically LVT and Waterproof floors.He has worked in a variety of channels, A&D, Contractor, Main street retail, and big box. His background knowledge in this category covers a variety of practical applications of various vinyl products, such as, sheet vinyl, glue down LVT, click/ floating LVT, Solid Polymer Core (SPC), Expanded Polymer core (WPC).His installation experience includes all the above also repair, plank replacement and Refinishing/ Refreshing Vinyl floors.

About The Author: Lavinia Rathbun

More posts by Lavinia Rathbun